Decoration Wall Panel Roll Forming Machine

Basic Info

Model No.: TG-0047

Product Description

The polyurethane energy saving insulation board is made of color coated steel plate. After rolling, the polyurethane foam liquid is injected into the middle. After a certain process of high temperature, foaming and curing, the core material is strongly bonded to the panel after processing. It has good heat preservation, fire protection, energy saving, environmental protection and so on. At present, Wallboard Roll Forming Machine is widely used in the enclosure system of large supermarket, office building, stadium, terminal building and large industrial factory building. As a building plate, polyurethane sandwich board is a combination of energy saving, green environmental protection, and art building. Decoration Wall Panel Roll Forming Machine adopts double drive to roll extrusion technology, the product surface is smooth, smooth and high density. Wall Panel Roll Forming Machine of new building wall panels is being realized. It has greatly reduced the labor intensity of the production workers. Completely changed the previous formwork, flat mold casting molding many disadvantages. Decorative Wallboard Roll Forming Machine is mainly used in building wall insulation, building roof insulation system, steel plate roof insulation, ground insulation, thermal insulation, pavement foundation, and can be widely used in many fields, such as refrigerator car, square ground, airport and so on.

1. Profile Drawing and Products for Reference

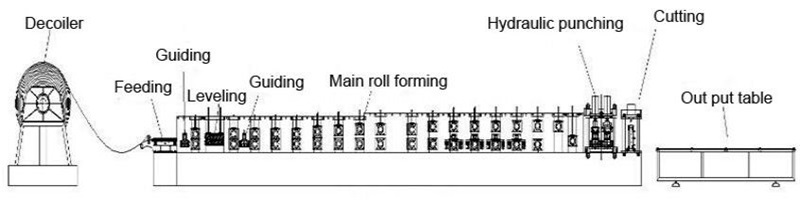

2. Working Flow

Decoiler---- feeding with guide--- Punching---- Roll forming---- Cutting---- Products collecting

3. Main technical data

| COMPONENT FOR Decoration Wall Panel Roll Forming Machine | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

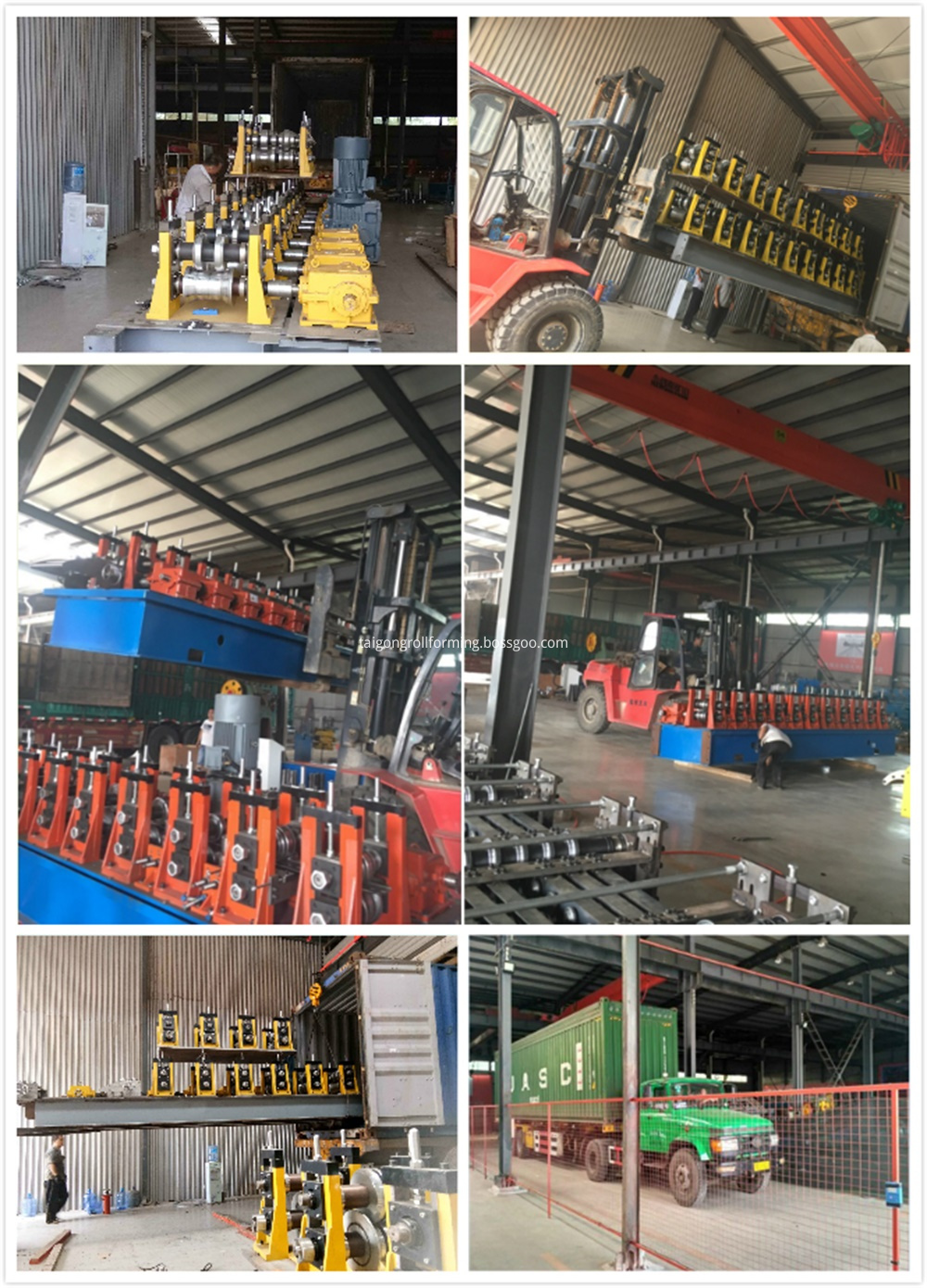

4. Equipment for Reference

5. Scene application

6. Customer

7. Loading

FAQ

Q: How can I contact you?

A: Please look at my contact card. You can talk to me anytime. Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you.

Q: What is the status of After-sale Services for customers and machineries?

A: Engineers available to service machinery overseas. But the customers/buyer should pay for installation and commissioning fee 100$/day to our point account. We will provide the technical support for the whole life of the equipment and free training.

Q: How to visit our company?

A: 1. Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou one hour, then we can pick up you. 2. Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou 4.5 hours, then we can pick up you. 3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou one hour, then we can pick up you.

Q: How many years since you have been in this field?

A: Our company has been producing Roll Forming Machines for almost 20 years. We have rich experience for manufacturing and designing Cold Roll Forming Machine.

8. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product Categories : Light Gauge Steel Frame Roll Forming Machine > Decoration Wall Panel Roll Forming Machine